Subchapter 4.4

Conveying systems

In this chapter, you will learn about typical hazards associated with different types of conveyor systems and how to reduce risks using safeguards, area separation, and design principles based on EN 619. The chapter also outlines safe access strategies for maintenance and highlights critical zones where extra protection is required

Understanding conveyor safety

Conveying systems come in a wide variety of types: belt, roller, carrying-chain, underfloor-chain, plate, tote, overhead, rail-bound conveyors and many others.

Many conveying systems are designed “inherently safe”, that is, they entail no or only minor residual risks and may thus operate without additional safeguarding. But safety also depends on the loads, the type of conveyor, and its interfaces with other machinery.

A comprehensive safety standard on this is EN 619. This standard to date is unmatched by other standardization systems. ASME B20.1 for the USA presents similar requirements but is not as comprehensive. In the following we highlight a few of the safety concerns and the strategies for coping with them.

Managing access and interface hazards

Automated warehouses often require staff to cross paths with machinery whether to move between zones, access other systems, or perform maintenance. Interfaces and access points introduce serious safety risks if not properly safeguarded.

Entry and exit openings at the interfaces to other machinery, as well as staff cross-over points, can pose considerable risks (see the section on “Fixed automation systems” above for typical risks and appropriate safeguards). Another common risk in large automated facilities is related to authorized or unauthorized access to hazardous areas, commonly referred to as “whole body access.”

Technicians entering such areas for troubleshooting or maintenance must be protected, even when nearby parts of the system continue operating. Unintended start-up of machinery sections can cause severe injury or even fatalities if adequate safety measures are not in place.

Knowledge in a nutshell

Key requirements and limit values for entry/exit openings in conveying systems and S/R machines*

Important: Shearing and crushing are considered avoided if the force actuated by the load is < 150 N. If that value is exceeded or there is risk from moving parts of the machinery, install safeguards.

Guard fencing:

- Height min. 2000 mm (also between restricted and danger area) to avoid climbing over.

- Space between bottom edge and floor max. 240 mm e.g. for cleaning or removal of loads (min. safety distance to hazard then is 850 mm).

- If the height of the protective structure at the entry/exit points is < 1000 mm, the horizontal safety distance to the nearest hazard must be min. 1400.

- Max. size of entry/exit openings so they are not considered to allow "whole body access":

180 x 300 mm.

240 x 240 mm.

800 x 800 mm. - Max. gap between the conveying level and the top of the opening 500 mm.

- Safe clearances between moving loads and fixed objects, if the opening is larger than listed above:

Full body: 500 mm.

Arms only: 120 mm.

For any value > 120 mm and up to 500 mm: additional safeguards are needed (nets, mats or sloping plates which prevent standing and walking). - Dimensions of tunnel around the conveyor entry/exit point to be used if space above the conveying level exceeds 500 mm:

Max. 600 mm high, tunnel length min. 800 mm.

Max. 800 mm high, tunnel length min. 1000 mm.

Max. 1000 mm high, tunnel length min. 1200 mm.

* The information is based on EN 619, EN 528 and ANSI B11.0, B11.19.

Safeguarding of conveyors

In addition to inherently safe design, most conveyor systems require extra protective measures to reduce the risk of injury.

The examples below highlight common safeguarding solutions based on

EN 619 and industry best practices.

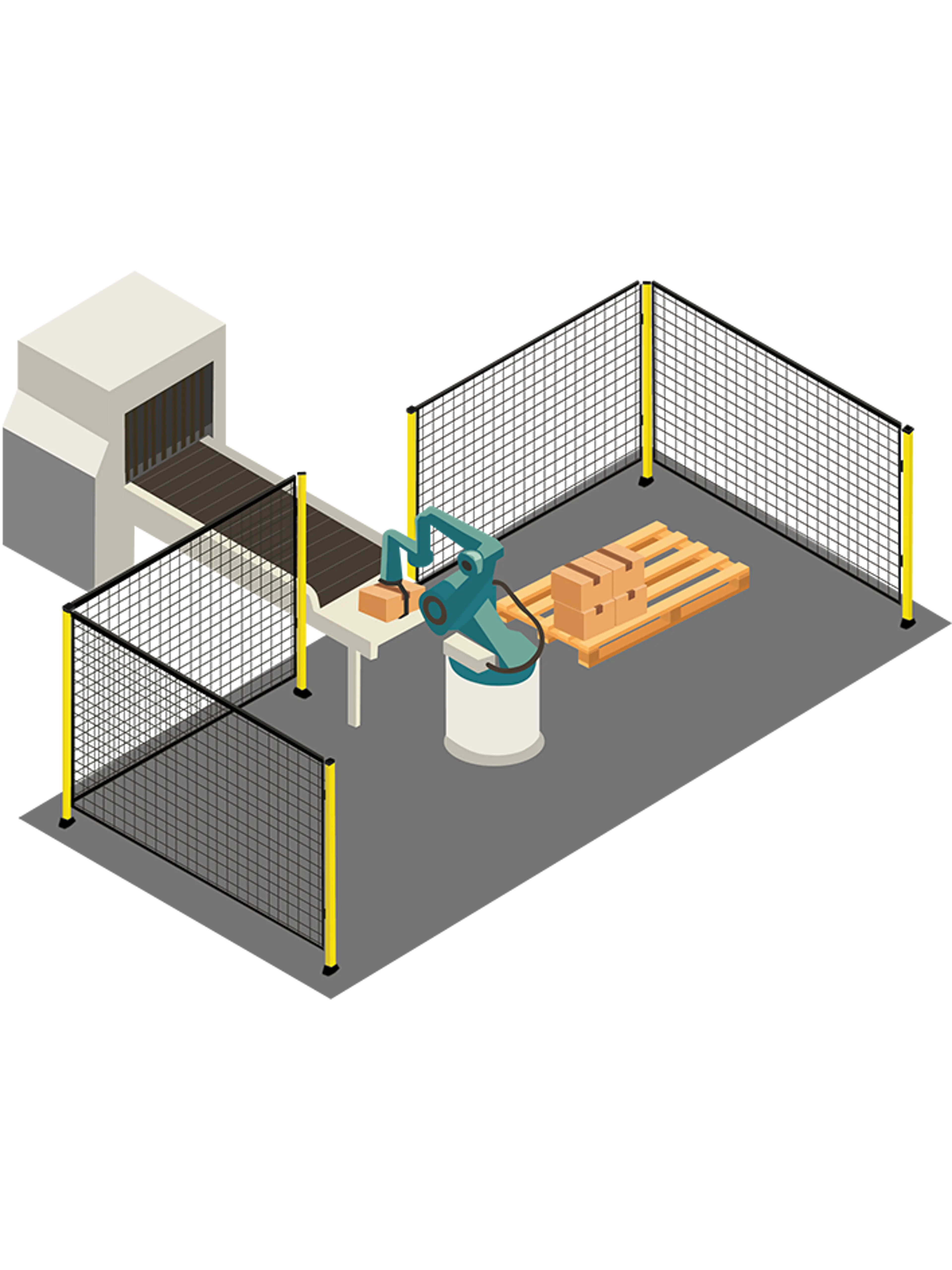

Typical safeguarding measures include:

- Guard fencing with interlocked doors.

- Light barriers, laser scanners, or contact mats.

- Barriers preventing access to hazardous spots (e.g. pedestrian barriers, sloping plates, foam blocks).

- Enclosed housings or "tunnels" around the conveyor (see "Knowledge in a nutshell" above).

If the opening above the conveying level is higher than 500 mm, measures are needed to prevent people from walking or crawling on top of or across the conveyor.

Suitable options include:

- Light curtains, pressure-sensitive mats, automatic gates with muting, or swinging doors.

- Designing conveyors so that the space between fixed and moving parts is less than 120 mm.

- Keeping frame widths below 40 mm.

- Using chains that are less than 40 mm wide to prevent stepping.

- Installing fixed guards, nets, mats, inclined plates, or roof-shaped profiles along the conveyor.

- Using mats between chains on chain conveyors.

See EN 619 for further details.

Risk area classification in EN 619

Safe access for troubleshooting, maintenance and restart after interventions should be ensured by a well thought-out “area concept” with suitable safeguards.

EN 619 presents a concept with five different areas representing different risk levels:

- Public area (low risk) - entered by the general public, for instance in the baggage claim area of an airport.

- Workplace (low risk) - places where staff picks or packs goods (excluded are trouble shooting, cleaning, maintenance or repair tasks, which take place in restricted areas).

- Traffic area (medium risk) - accessible without opening or removing a guard or activating other safeguards.

- Restricted area (medium to high risk) - entered by qualified personnel only for maintenance, trouble shooting and repair work.

- Danger area (high risk) - here persons could be exposed to danger during operation of diverse kinds of conveying systems.

Selecting safeguards by area type

If an area concept is introduced, the areas must be clearly separated. The restricted and danger areas must only be accessible by opening or removing a guard or activating other safeguards.

- Restricted areas

Use guard fencing at least 1400 mm high. Access doors must be self-closing and self-locking. They do not need to be interlocked but must require a key from the outside and be openable without a key from the inside. Entrances must be at least 1000x1000 mm in size. - Danger areas

Use guard fencing at least 2000 mm high. Floor gaps should be no more than 240 mm (only if needed for cleaning), preferably 180 mm or less. Access doors must be interlocked, guard-locked, or fitted with a key transfer system. Follow operating mode requirements in EN 619. - Traffic areas and workstations

Use pedestrian or awareness barriers to keep people out of conveyor operating zones.

As an alternative to guards, you may install optoelectronic safety devices: